Let's start with a little introduction about milling machines and milling machine operations. A milling machine is a machine tool that cuts metal as the workpiece is fed against a rotating multipoint cutter. The milling cutter rotates at a very high speed because of the multiple cutting edges, it cuts the metal at a very fast rate. This machine can also hold single or multiple cutters at the same time. This is why a milling machine has wide application in production work. This is better for other machines as regards accuracy and better surface finish. And also it is designed for machining a variety of tool room work.

This is why a milling machine has wide application in production work. This is better for other machines as regards accuracy and better surface finish. And also it is designed for machining a variety of tool room work.

Milling Machine Operations

The 14 different types of milling machine operations are as follow:

1. Plain Milling Operation

2. Face Milling Operation

3. Side Milling Operation

4. Straddle Milling Operation

5. Angular Milling Operation

6. Gang Milling Operation

7. Form Milling Operation

8. Profile Milling Operation

9. End Milling Operation

10. Milling Keyways, Grooves, and Slot

11. Gear Milling

12. Helical Milling

13. Cam Milling

14. Thread Milling

Types of Milling Machine Operations

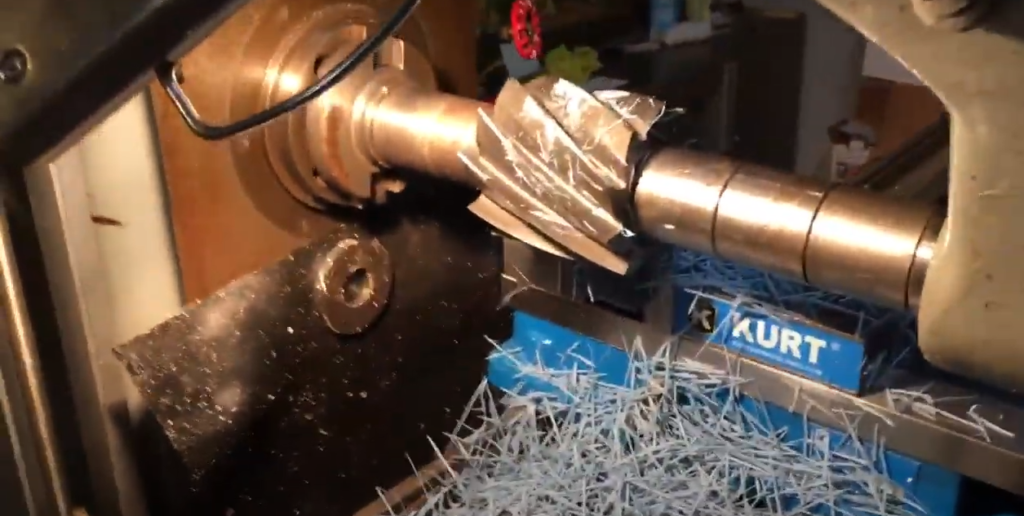

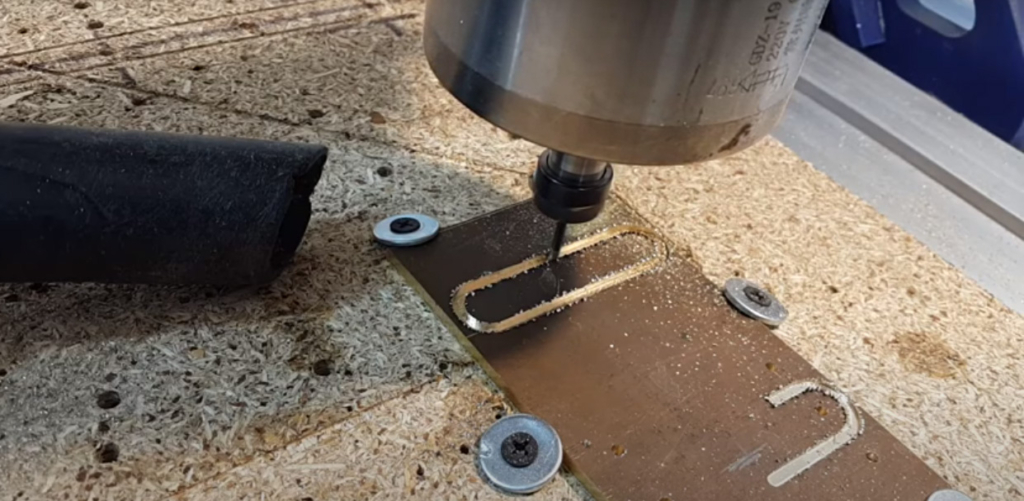

1). Plain Milling

- Plain milling is the most common type of milling machine operation.

- Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter.

- The operation is also known as slab milling.

- To perform the operation, the work and the cutter are secured properly on the machine.

- The depth of cut is set by rotating the vertical feed screw of the table. And the machine is started after selecting the right speed and feed.

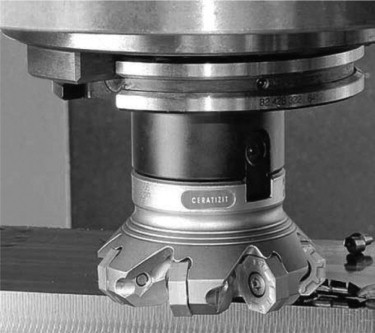

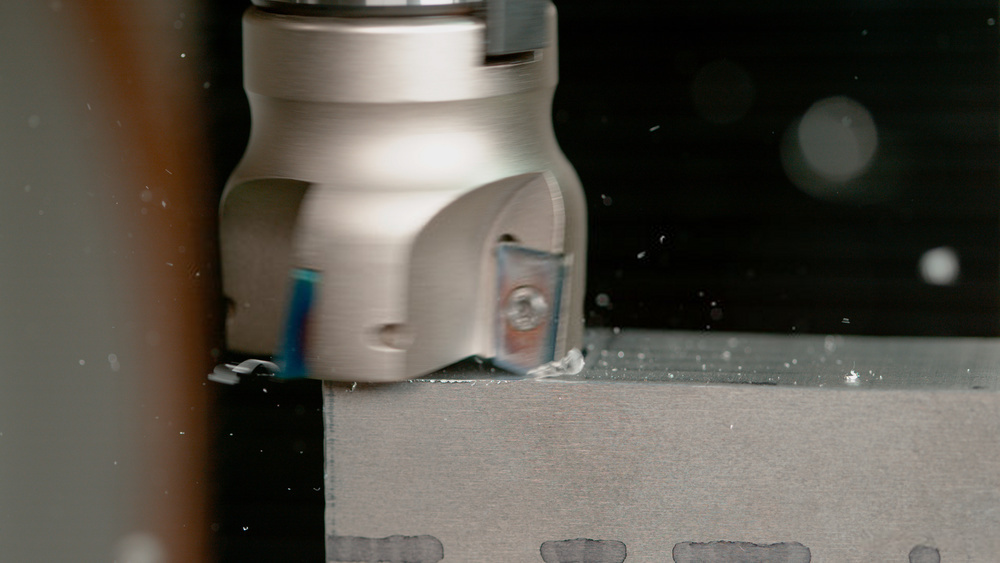

2). Face Milling

- Face milling is the simplest milling machine operation.

- This operation is performed by a face milling cutter rotated about an axis perpendicular to the work surface.

- The operation is carried out in plain milling, and the cutter is mounted on a stub arbor to design a flat surface.

- The depth of the cut is adjusted by rotating the crossfeed screw of the table.

3). Side Milling

- Side milling is the operation of producing a flat vertical surface on the side of a workpiece by using a side milling cutter.

- The depth of cut is set by rotating the vertical feed screw of the table.

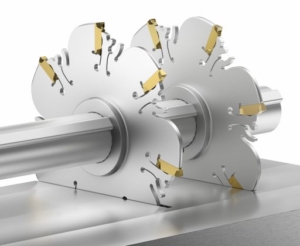

4). Straddle Milling

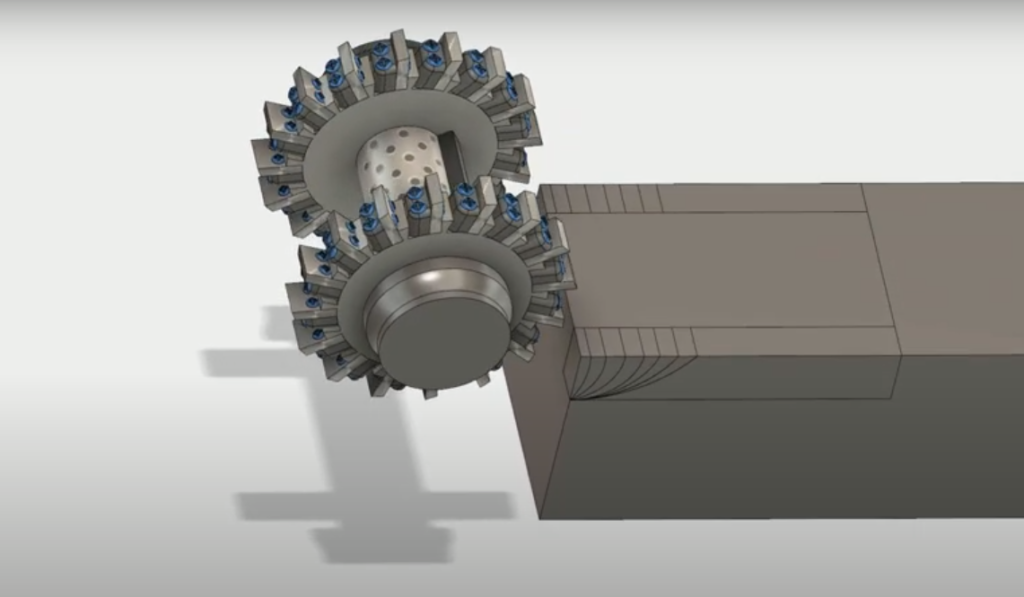

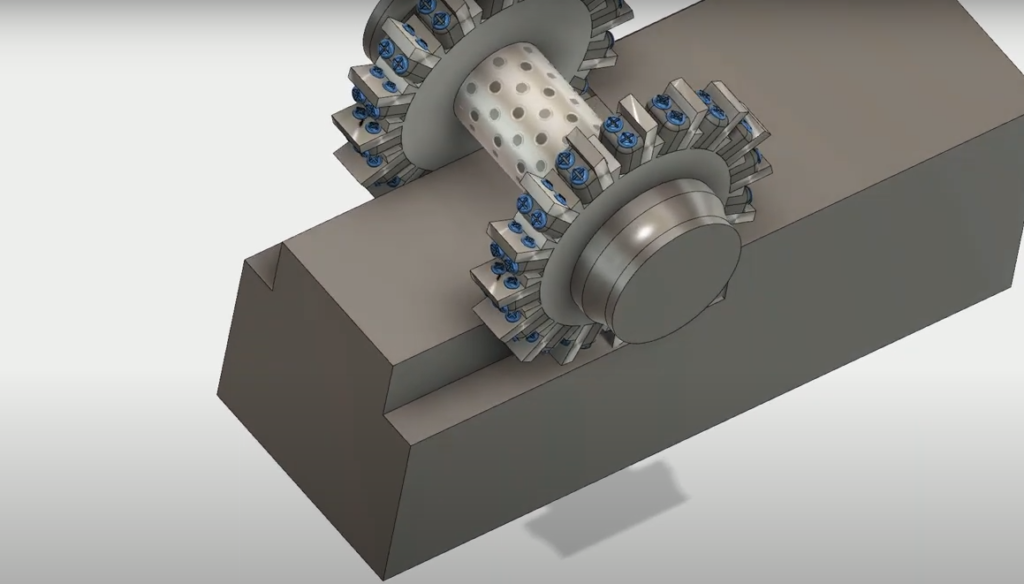

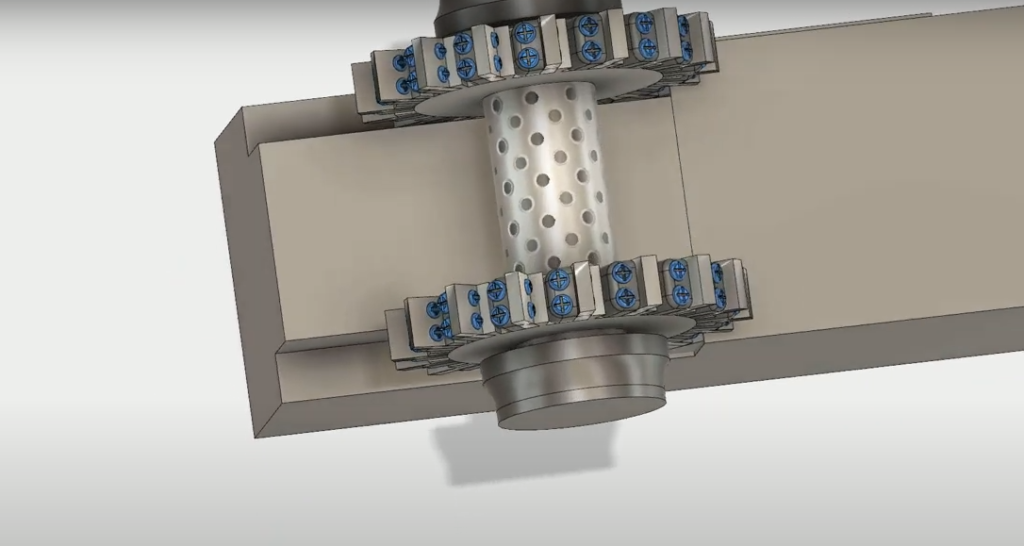

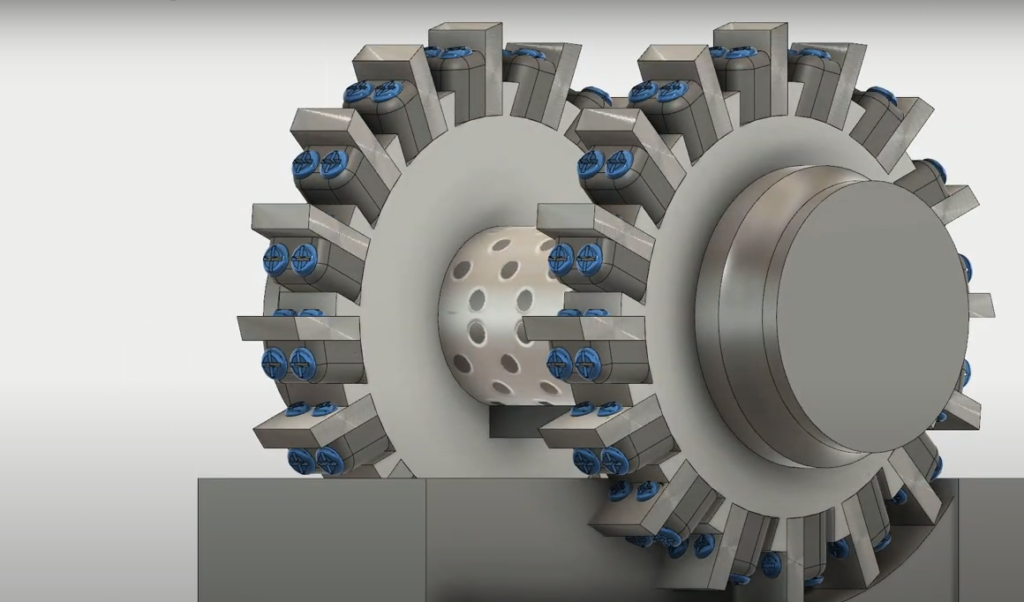

- Straddle milling is the operation of producing a flat vertical surface on both sides of a workpiece by using two side milling cutters mounted on the same arbor.

- Distance between the two cutters is adjusted by using suitable spacing collars.

- Straddle milling is commonly used to design square or hexagonal surfaces.

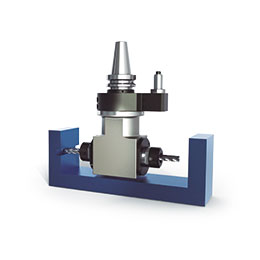

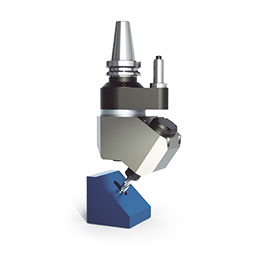

5). Angular Milling

- Angular milling is the operation of producing an angular surface on a workpiece other than at right angles of the axis of the milling machine spindle.

- The annular groove may be single or double angle and may be of varying included angle according to the type and contour of the angular cutter used.

- One simple example of angular milling is the production of V-blocks.

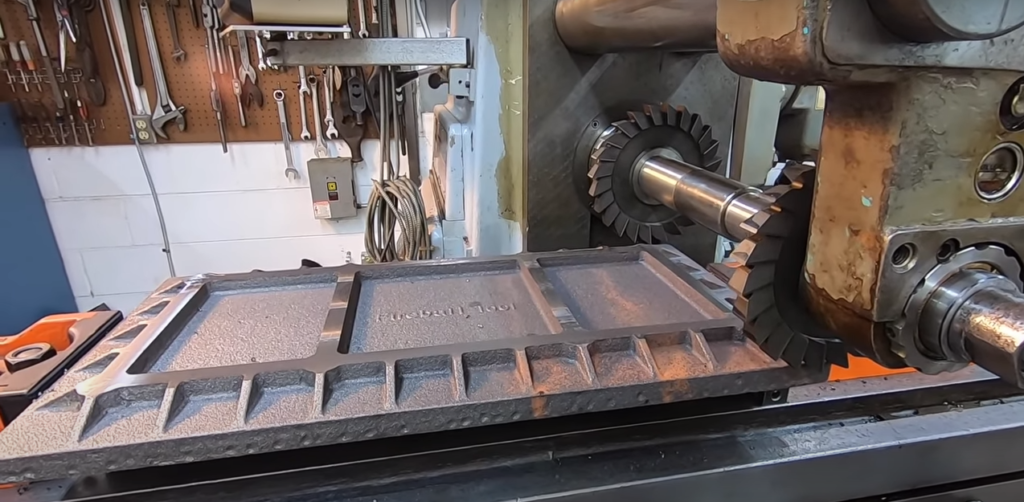

6). Gang Milling

- Gang milling is the operation of machining several surfaces of a workpiece simultaneously by feeding the table against a number of cutters having the same or different diameters mounted on the arbor of the machine.

- The method saves much machining time and is widely used in repetitive work.

- The cutting speed of a gang of cutters is calculated from the cutter of the largest diameter.

7). Form Milling

- Form milling is the operation of producing irregular contours by using form cutters.

- The irregular shape may be convex, concave, or of any other shape. After machining, the formed surface is inspected by a template gauge.

- The cutting rate for form milling is 20% to 30% less than that of plain milling.

8). Profile Milling

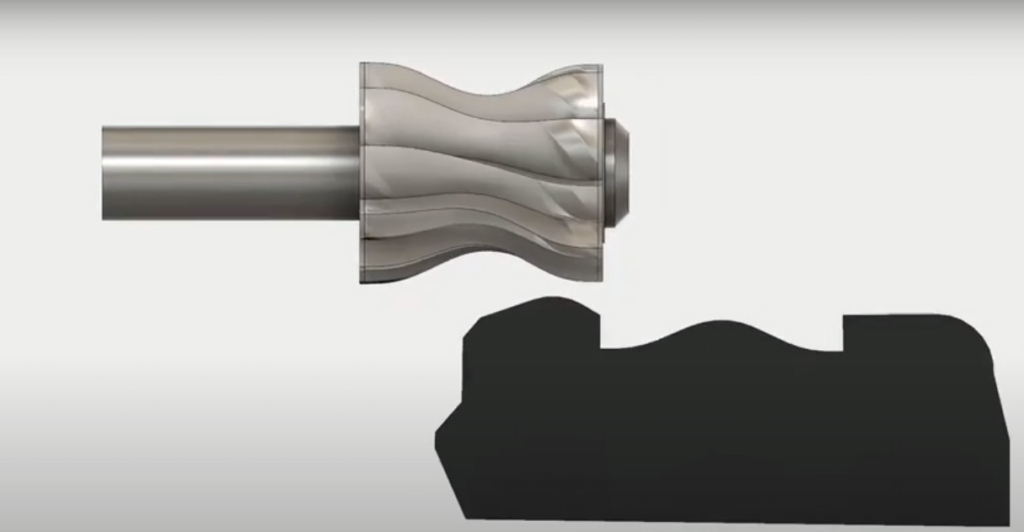

- Profile milling is the operation of reproduction an outline of a template or complex shape of a master dies on a workpiece.

- Different cutters are used for profile milling. An end mill is one of the widely used millings cutters in profile milling work.

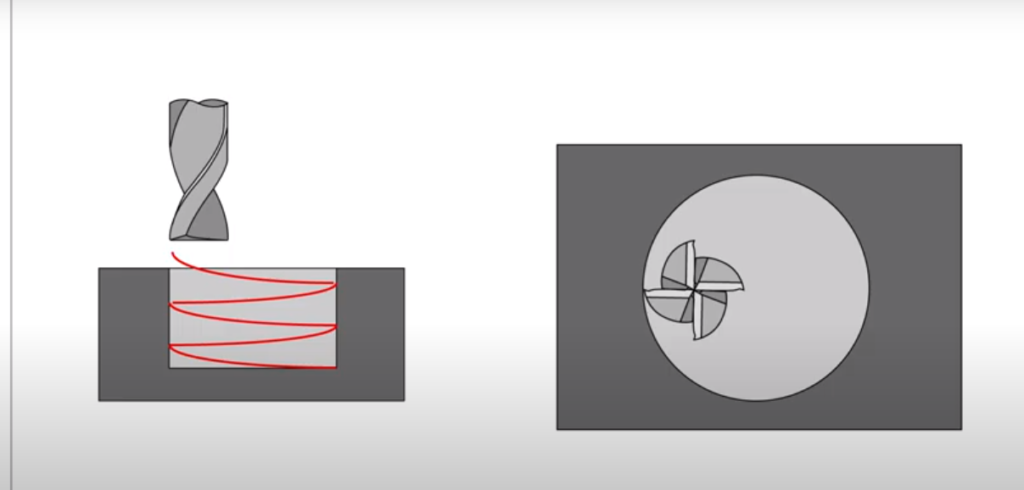

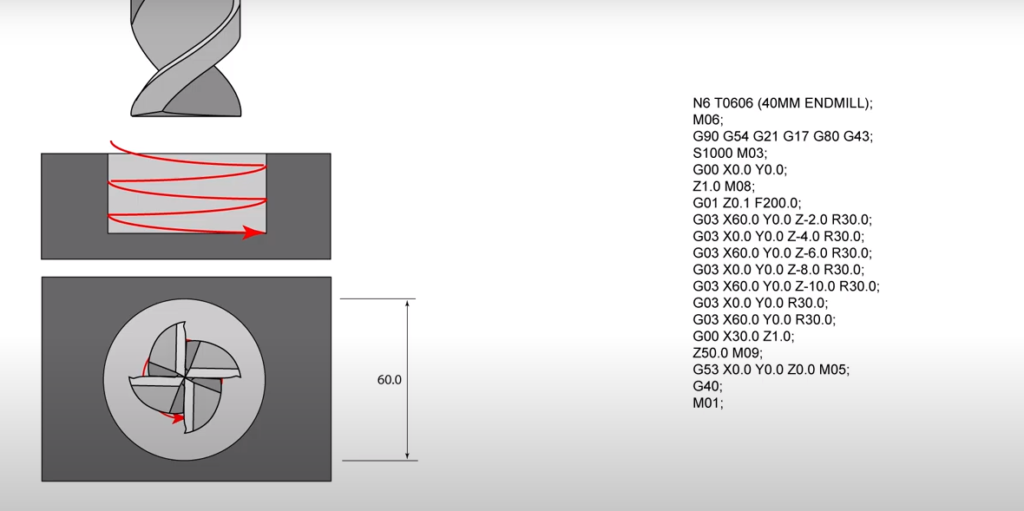

9). End Milling

- The end milling is the operation of producing a flat surface that may be vertical, horizontal, or at an angle in reference to the table surface.

- The cutter used is an end mill. The end milling cutters are also used for the production of slots, grooves, or keyways.

- A vertical milling machine is more suitable for end milling operation.

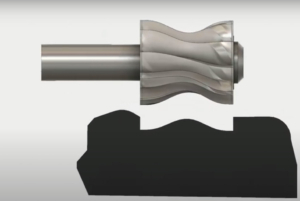

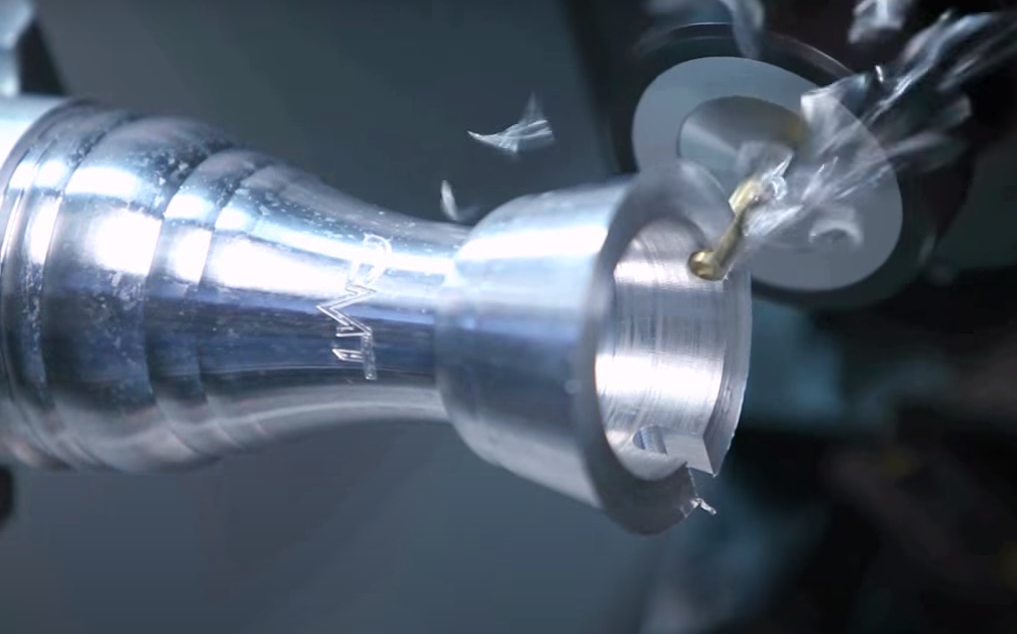

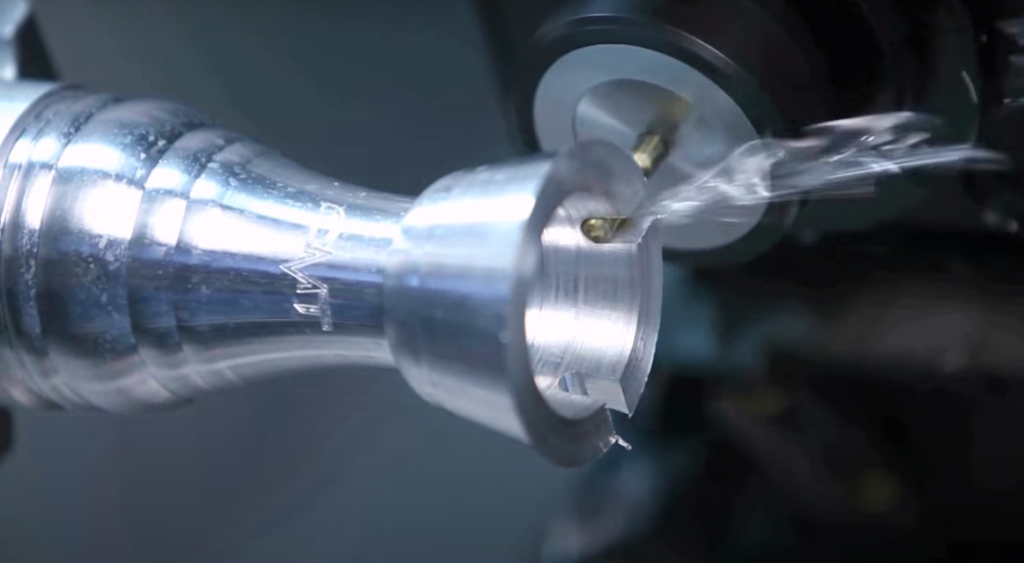

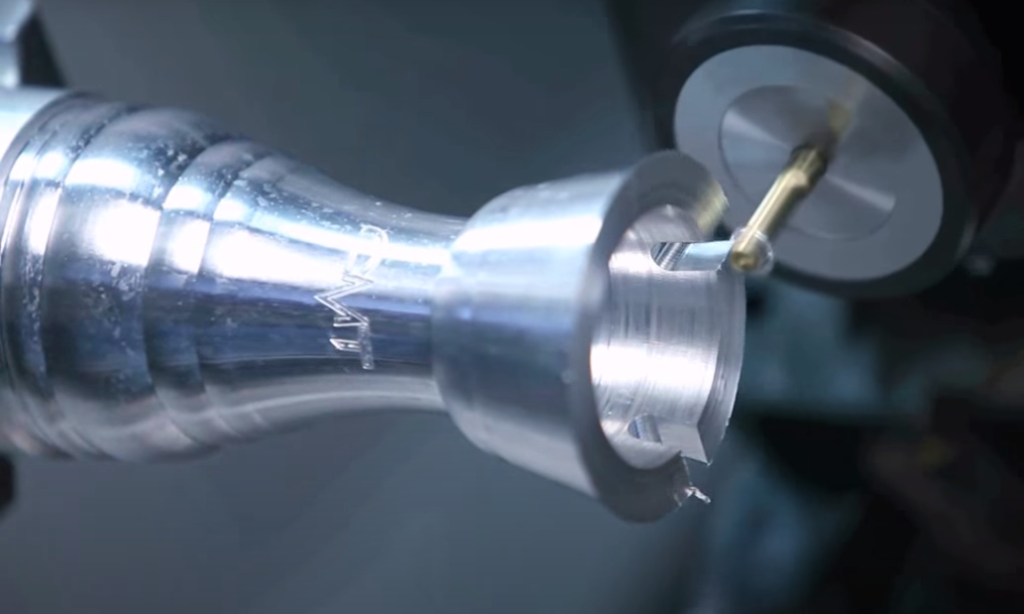

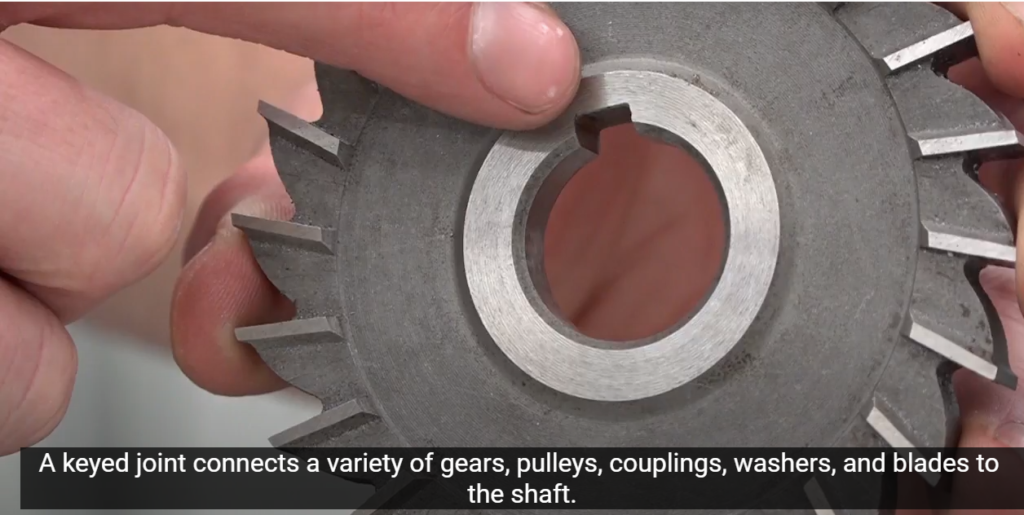

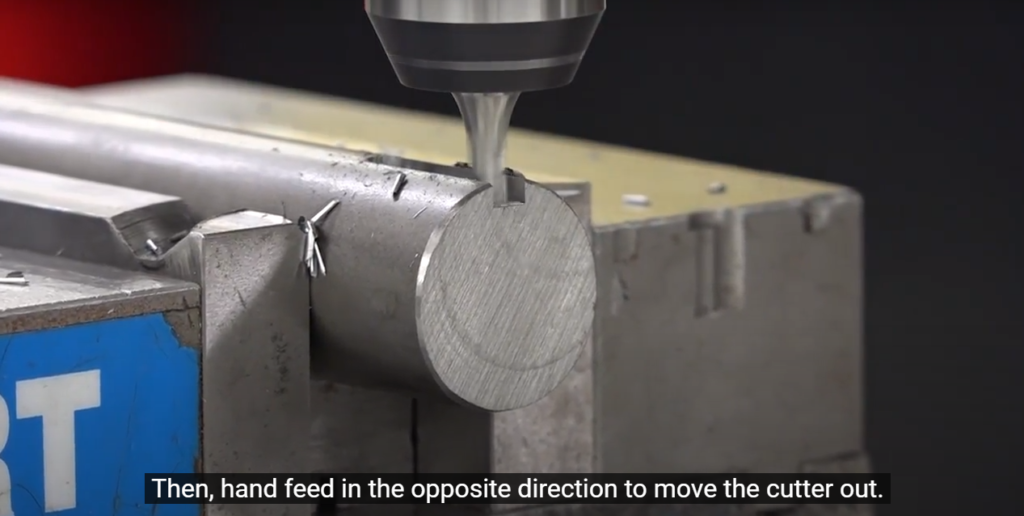

10). Milling Keyways, Grooves, and Slots

- The operation of producing keyways, grooves, and slots of varying shapes and sizes can be performed in a milling machine.

- It is done by using a plain milling cutter, a metal slitting saw, an end mill, or a side milling cutter.

- The open slots can be cut by a plain milling cutter, a metal slitting saw, or a side milling cutter. The closed slots are produced by using endmills.

- A dovetail slot or T-slot is manufactured by using special types of cutters designed to give the required shape to the workpiece.

- The second slot is cut at right angles to the first slot by feeding the work past the cutter.

- A woodruff key is designed by using a woodruff key slot cutter.

- Standard keyways are cut on the shaft by using side milling cutters or end mills.

- The cutter is set exactly at the centerline of the workpiece and then the cut is taken.

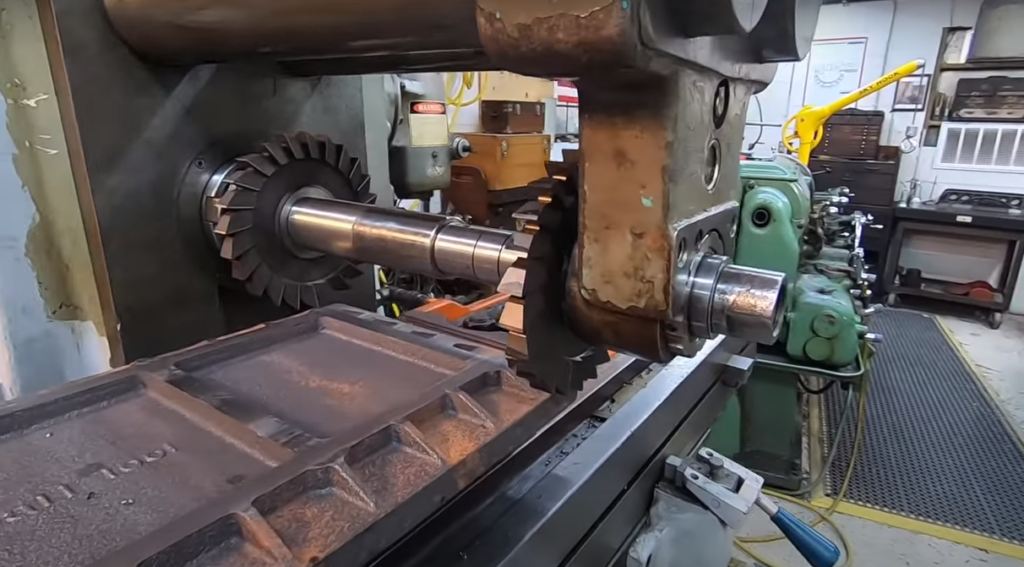

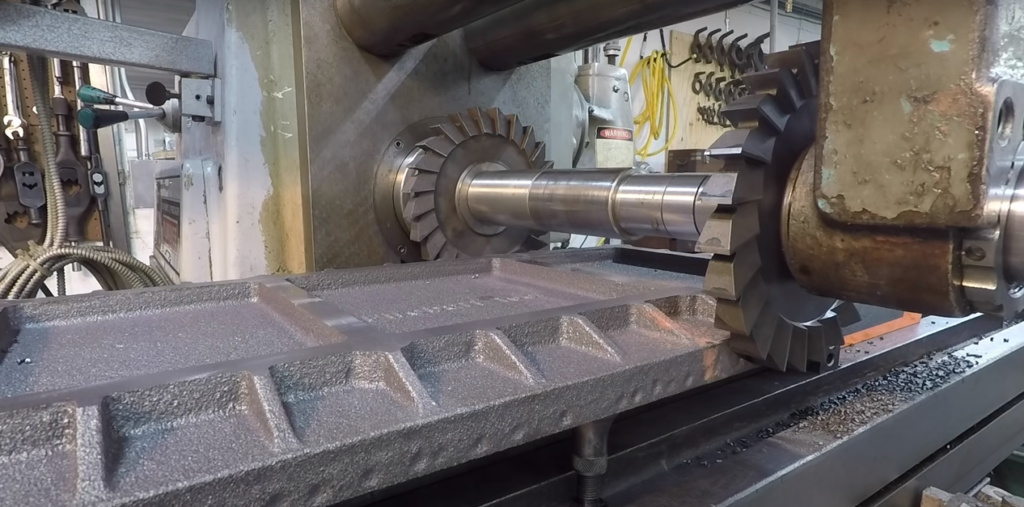

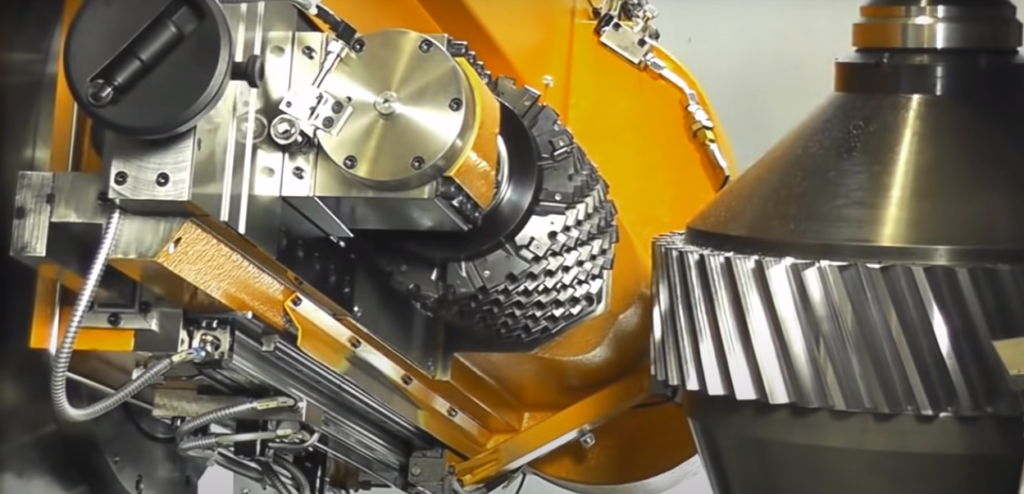

11). Gear Cutting

- The gear cutting operation is performed in a milling machine by using a form-relieved cutter. The cutter may be a cylindrical type or end mill type.

- The cutter profile fits exactly with the tooth space of the gear.

- Equally spaced gear teeth are cut on a gear blank by holding the work on a universal diving head and then indexing it.

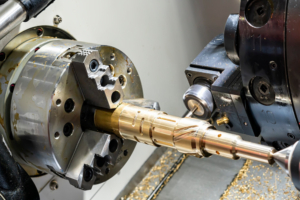

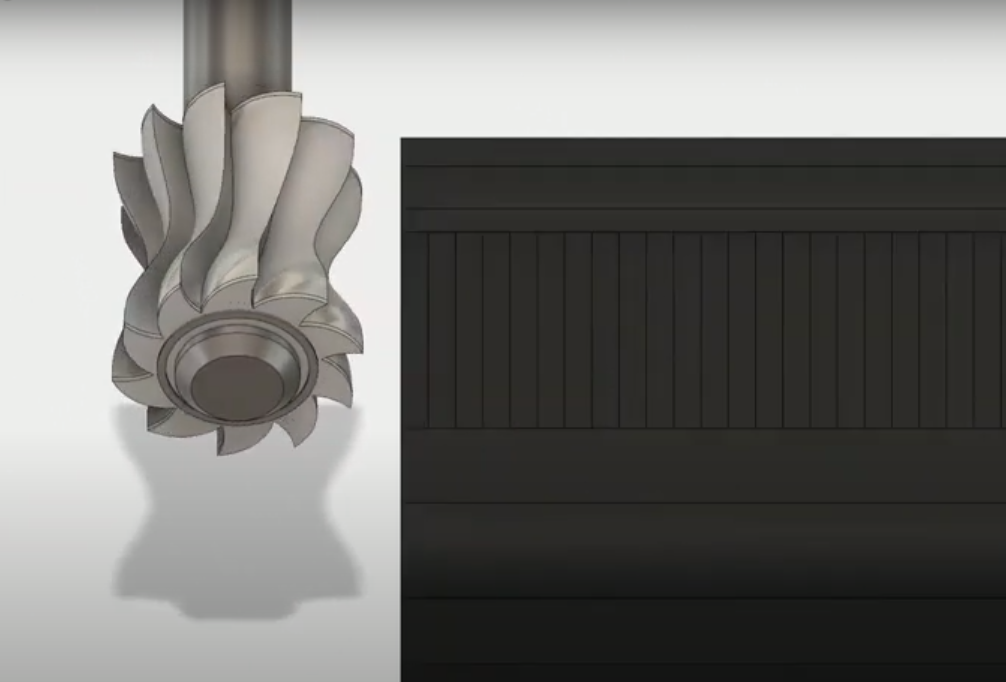

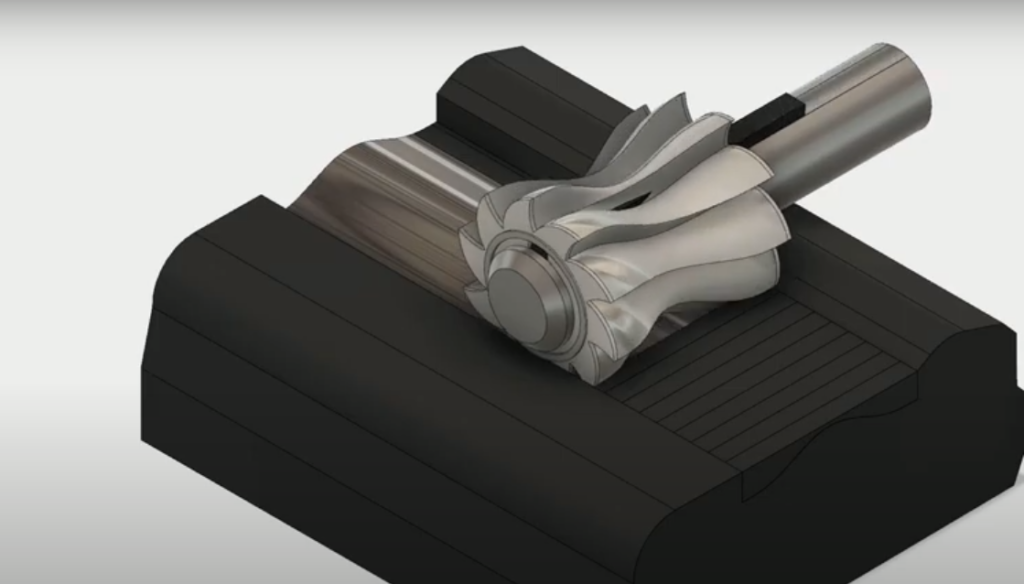

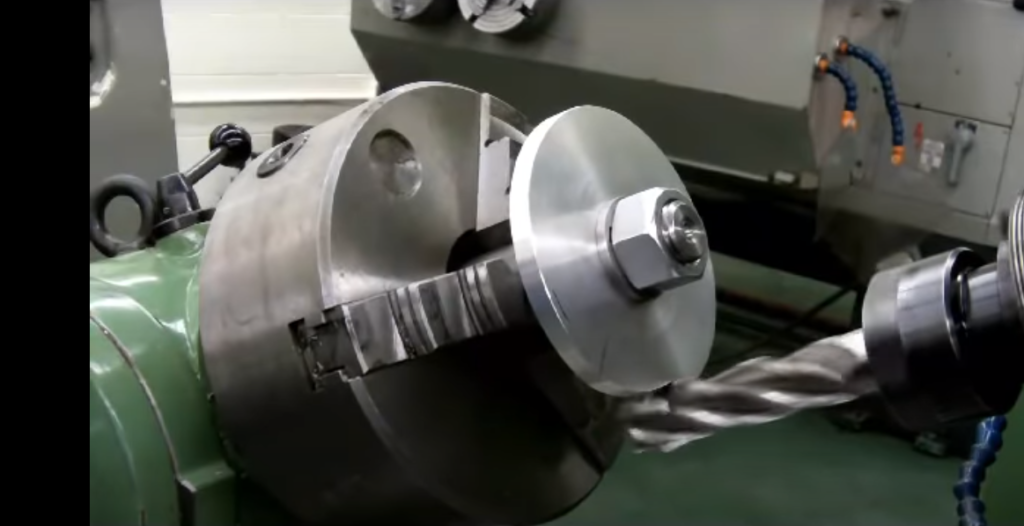

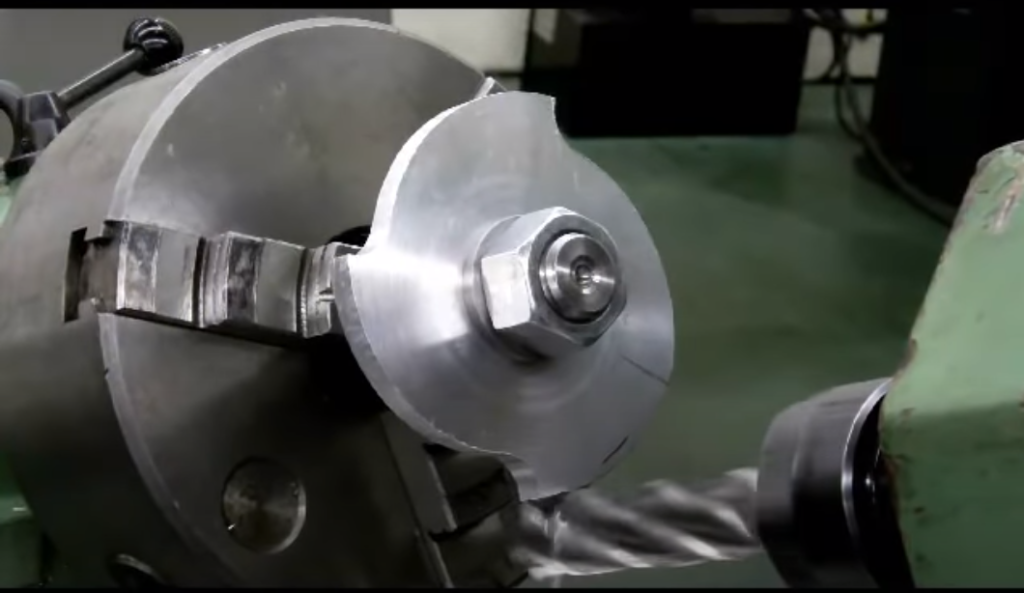

12). Helical Milling

- Helical milling is the operation of producing helical flutes or grooves around the periphery of a cylindrical or conical workpiece.

- The operation is performed by rotating the table to the required helix angle. And then by rotating and feeding the workpiece against the rotary cutting edges of a milling cutter.

- Production of the helical milling cutter, helical gears, cutting helical grooves or flutes on a drill blank or a reamer.

13). Cam Milling

- Cam milling is the operation of producing cams in a milling machine by the use of a universal dividing head and a vertical milling attachment. The cam blank is mounted at the end of the dividing head spindle and an end mill is held in the vertical milling attachment.

- The axis of the cam blank and the end mill spindle should always remain parallel to each other when setting for cam milling. The dividing head is geared to the table feed screw so that the cam is rotated about its axis while it is fed against the end mill. The axis of the cam can be set from 0 to 90° in reference to the surface of the table for obtaining a different rise of the cam.

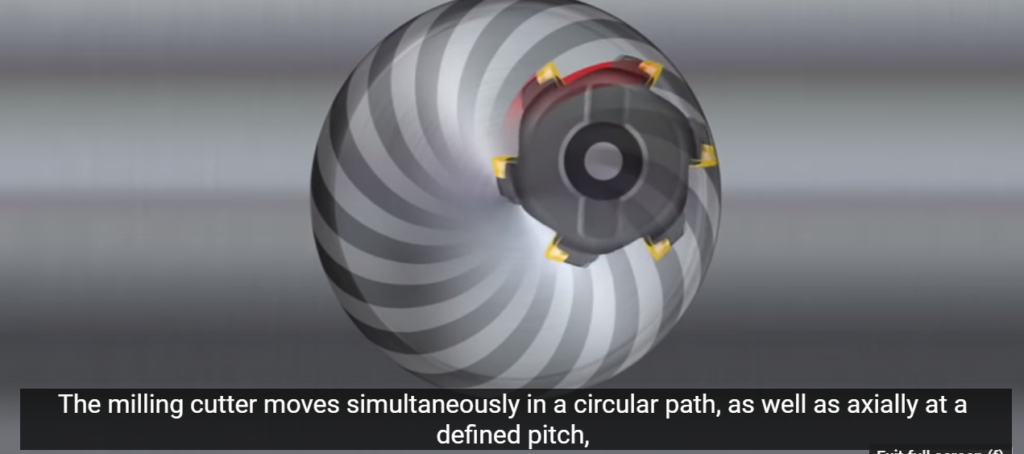

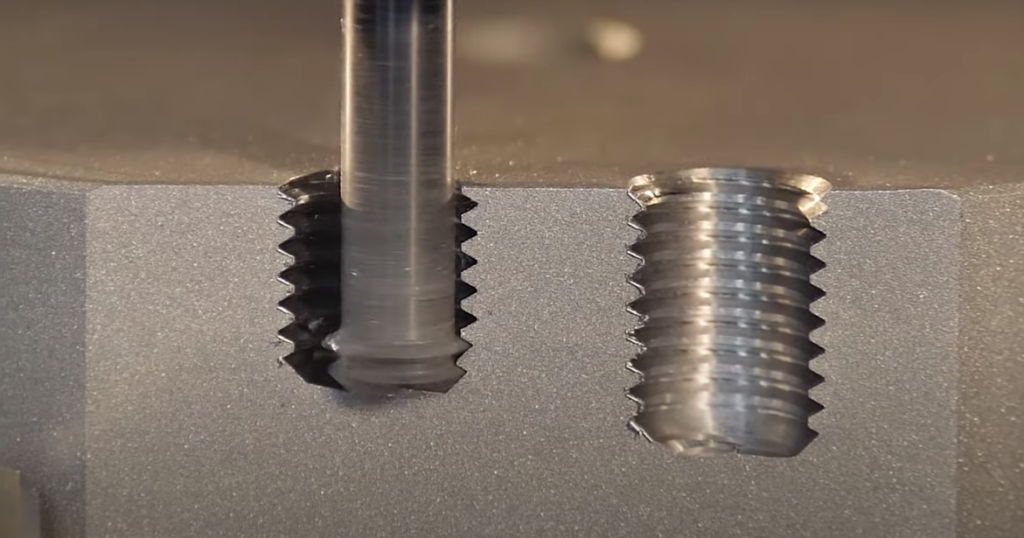

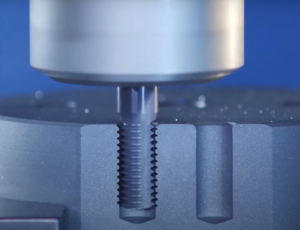

14). Thread Milling

- The thread milling machine operations are used to produce threads by using a single or multiple

thread milling cutter. Thread milling operation is performed in special thread milling machines to

produce accurate threads in small or large quantities. - The operation requires three driving motions in the machine. One for the cutter, one for the work

and the third for the longitudinal movement of the cutter.

- When the operation is performed by a single thread milling cutter, the cutter head is swiveled to the exact helix angle of the thread. The cutter is rotated on the spindle and the workpiece is revolved slowly about its axis.

- The thread is completed in one cut by setting the cutter to the full depth of the thread and then feeding it along the entire length of the workpiece.

- When the thread is cut by a multiple thread milling cutter, the cutter axis and the work spindle are set parallel to each other after adjusting the depth of cut equal to the full depth of the thread.

- The thread is completed by simply feeding the revolving cutter longitudinal through a distance equal to the pitch length of the thread while the work is rotated through one complete revolution.

Comments(0)